Plug valves control gas or liquid flow under high pressure in a process system. Usually, the valves are conically tapered and can start or stop fluid flow through quarter-turn manual motion. In addition, they control flow through moderate throttling.

Any system containing high-pressure fluids requires plug valves to control fluid flow. Each valve has hollow passageways that allow flow through it when opened. Besides, it has a dual port system: an open position to allow flow and a closed position to stop the flow. So, you should know how the valves work.

What are plug valves? Learn what they are, how they work, and the available types. Click To TweetLet’s find out how plug valves work, their applications, and the types available.

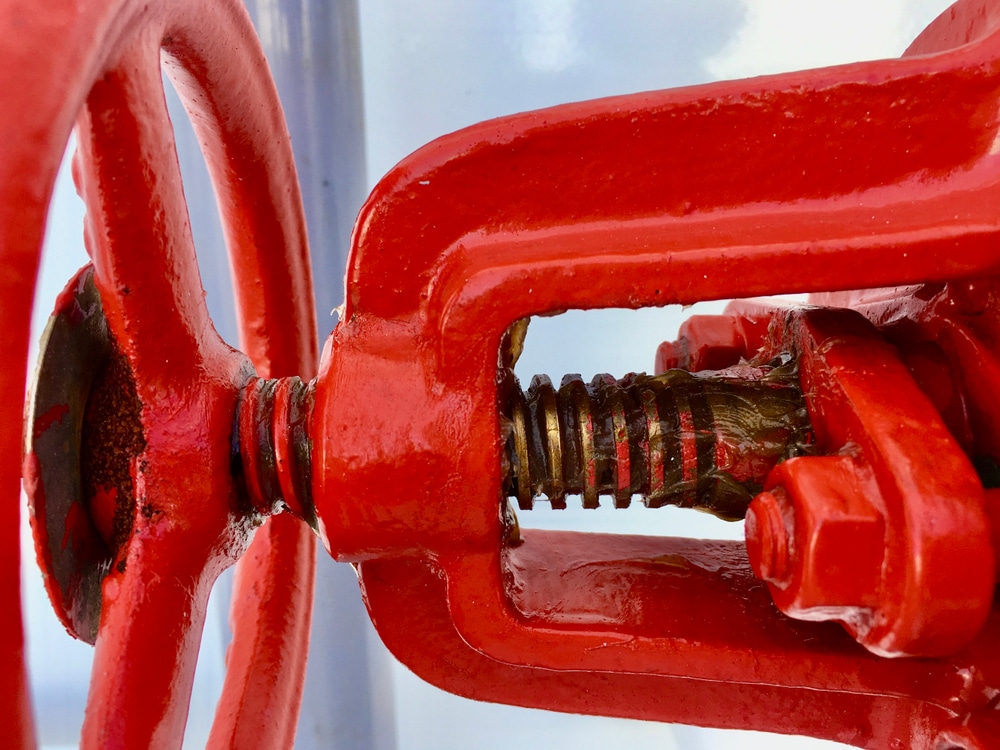

How They Work

Plug valves have hollow passageways, so when the valve makes a quarter-turn motion, it aligns the pipe and the hole, opening the channel. Then, if you turn the valve to a 90-degree angle from the open position, it sits across the pipe, closing the passage. There are two types of valves based on port openings: two-way and three-way plug valves.

Plug Valve Uses

Plug valves are very reliable valves. Their smooth design, leak-tight service, inline maintenance capabilities, multi-port design options, and minimal resistance to fluid flow make them ideal for applications such as:

- Directional flow control

- Handling of gas or liquid fuels

- Controlling low-pressure, low-temperature services

- Regulation of fluids with suspended solids, like slurries

Types of Plug Valves

Here are the types of plug valves you should know.

- Lubricated Plug Valves: Ideal for dirty upstream applications as they can handle corrosive and abrasive materials without getting clogged. At Lubchem, we make lubrication for these types of valves.

- Non-Lubricated Plug Valves: These are ideal for low-maintenance applications, and examples include lift-type, elastomer-sleeved, and fully lined plug valves.

- Expandable Plug Valves: This type of plug valve has multiple components that operate in a complex rotation motion to avoid wear or abrasions to the seals.

- Eccentric Plug Valves: These are suitable for applications that require a higher seating force and reduced friction from open to a closed position.

Shop at Lubchem

So why do we want to talk about different types of plug valves, when we only offer products related to one type of valve plug? Well, at Lubchem, we want to ensure that our clients are making an informed decision on what equipment they need. That being said, we have all the plug valve sealants you could need, so be sure to check out our catalog to find what you are looking for.

Contact us today to order a wide range of valve lubrication.