In the vast world of industrial machinery, one key player stands out for precise fluid regulation—the plug gate ball valve. As industries progress, understanding these valves becomes crucial. Join us on a journey through the basics of plug gate ball valves in a simple guide.

The Anatomy of Plug Gate Ball Valves

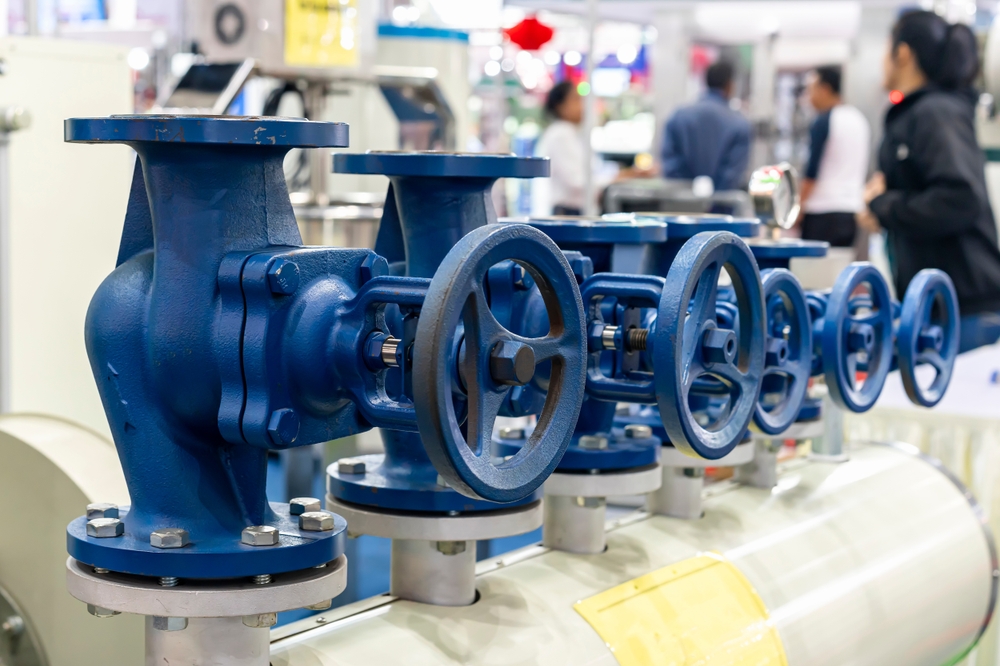

At the core of fluid control in industries, the plug gate ball valve is designed for precision and reliability. Its purpose is to tightly seal, effectively controlling the flow of liquids or gases through pipelines. This valve consists of a closure element called the “ball,” a seat, and actuators for control. Stem mechanisms connect the actuator to the ball, ensuring precise movements.

Seals and sealants, often made of resilient materials, enhance the valve’s ability to create a secure and leak-tight seal. Diverse industries demand varied valve designs. Plug gate ball valves come in floating, trunnion-mounted, and multi-port types, each tailored to specific needs. This section explores these configurations for optimal selection.

Operations Demystified

The valve’s seamless operation follows a systematic process, from a closed position to controlled fluid flow. Understanding this sequence forms the basis for appreciating the valve’s effectiveness. Plug gate ball valves regulate and control substance flow within pipelines. This includes managing flow rates, isolating pipeline sections, and achieving secure shut-offs when necessary.

The section emphasizes the valve’s significance in maintaining optimal fluid control in industries. In the oil and gas industry, plug gate ball valves shine. They contribute to seamless operations, enhance safety, and navigate challenges in extracting, transporting, and refining resources. From drilling to processing, these valves play a pivotal role.

Significance in Industrial Processes

Efficiency is key, and plug gate ball valves contribute to fluid handling efficiency by minimizing friction, reducing energy consumption, and optimizing overall system efficiency.

These valves influence overall system performance, addressing pressure control, pipeline stability, and leak prevention. Understanding their impact on system dynamics is crucial for optimal performance. Concrete examples highlight the effectiveness of plug gate ball valves in different industrial settings. Case studies showcase instances of increased efficiency, reduced downtime, and enhanced safety.

Types and Configurations

Understanding various valve types, such as floating, trunnion-mounted, and multi-port, equips readers to discern which suits their industrial requirements. Exploring configurations tailored to industry-specific demands ensures informed choices. This includes considerations for high-pressure environments or specialized fluid handling systems. Selecting the right valve type is paramount in industrial processes. Practical guidance is provided for matching valve types with specific applications based on factors like pressure, temperature, and fluid nature.

Lifecycle of Plug Gate Ball Valves

The valve’s journey begins with meticulous manufacturing, exploring material selection, precision engineering, and adherence to industry standards. Seamless integration requires careful planning, emphasizing alignment with system requirements, proper sealing techniques, and compliance with safety protocols. Ensuring longevity involves proactive maintenance, from routine inspections to addressing wear and tear and minimizing downtime and operational disruptions.

Trust Lubchem

In summary, plug gate ball valves are like the superheroes of fluid control in industries. They make sure everything flows smoothly and safely. Remember, these valves are not just gadgets; they’re essential for efficiency and reliability in industrial machines. So, keep exploring and stay curious about how they work. The industrial world is always changing, and understanding these valves helps us keep up with the progress.

Contact us to learn more about plug gate ball valves and sealants!