In the fast-paced and demanding world of the oil and gas industry, the reliable operation of machinery is paramount. From drilling rigs to pipelines, each component plays a vital role in ensuring smooth operations and maximizing productivity. However, the harsh conditions can take a toll on machinery performance.

That’s where degreaser cleaners step in. They are a solution to maintaining clean and well-lubricated equipment. In this blog post, we will delve into the crucial topic of degreaser cleaners and their pivotal role in machinery maintenance. We will explore the key qualities that make a degreaser effective for industrial machinery. This empowers you to make informed choices and keep your equipment running at its best.

Understanding Degreaser Cleaners

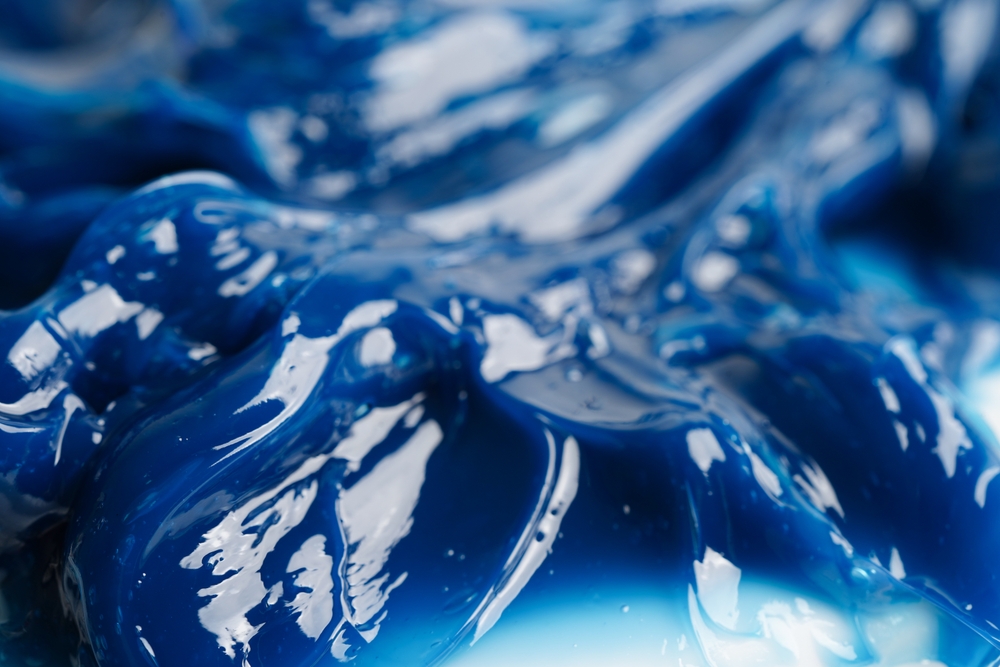

Degreaser cleaners are cleaning agents used in the oil and gas industry. Regular degreasing is crucial as it prevents breakdowns, boosts performance, and extends equipment lifespan. Each type offers unique benefits, allowing users to select the most suitable degreaser for their machinery cleaning needs.

Key Considerations for Choosing a Degreaser Cleaner

When choosing a cleaner for industrial machinery, prioritize safety for everyone. Look for an effective cleaner that can remove grease, oil, and contaminants from machinery surfaces. Ensure compatibility with different materials commonly found in machinery. Consider environmentally friendly options that minimize negative environmental impact. Lastly, choose a degreaser cleaner that is easy to use, saving time and effort during the cleaning process. By considering these factors, you can select the right degreaser cleaner for your industrial machinery needs.

Key Ingredients and Formulations

Solvents

Common solvents like hydrocarbons or citrus-based solvents are used in degreaser cleaners for their effectiveness in removing grease and contaminants from machinery surfaces. Hydrocarbons have strong cleaning power, while citrus-based solvents offer a safer and environmentally friendly option.

Surfactants

Surfactants in degreaser cleaners help break down and emulsify grease and oil, making them easier to remove. These compounds reduce the surface tension between water and grease/oil, enabling better mixing and dispersion of contaminants in the cleaning solution.

Corrosion inhibitors

Degreaser cleaners often contain corrosion inhibitors to protect machinery surfaces from damage. These inhibitors create a protective barrier on metal surfaces, preventing oxidation and the formation of rust. By inhibiting corrosion, they help extend the lifespan of machinery and reduce the need for repairs.

Shop With Lubchem

In summary, choosing a good degreaser cleaner is crucial for industrial machinery maintenance. It helps prevent breakdowns, optimize performance, and extend equipment lifespan. Consider factors like safety, effectiveness, compatibility, environmental impact, and ease of use when selecting a degreaser cleaner. Explore our range of valve cleaners, lubrication, and degreasers tailored for industrial machinery needs. Take proactive steps now to ensure the efficiency and longevity of your machinery, keeping your operations running smoothly and maximizing productivity.