Products

product search

Features paragraph

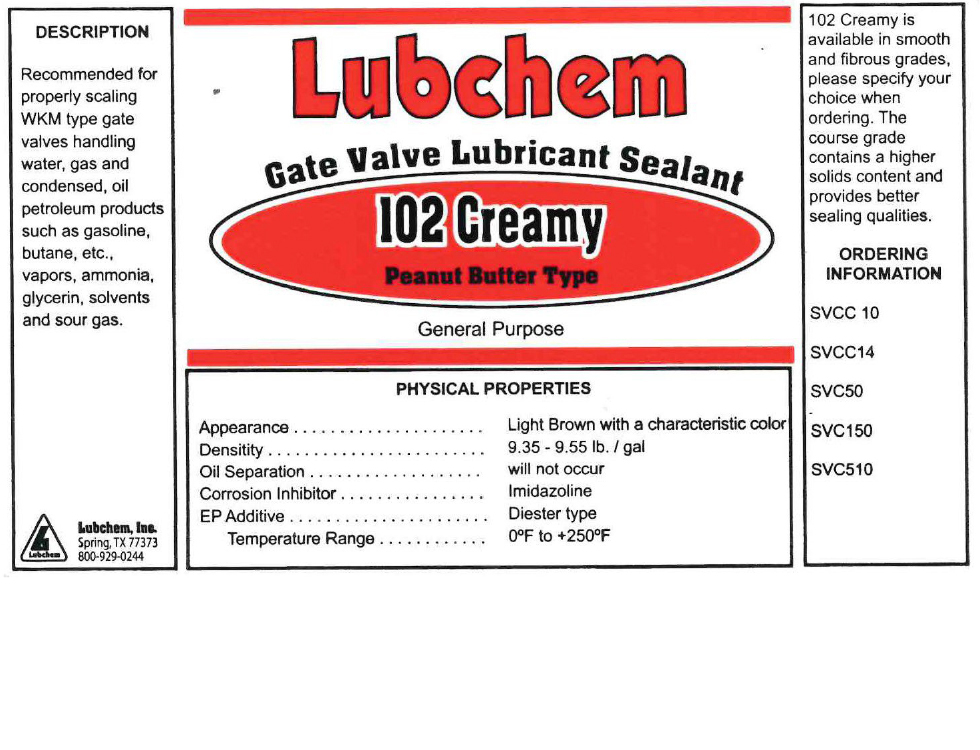

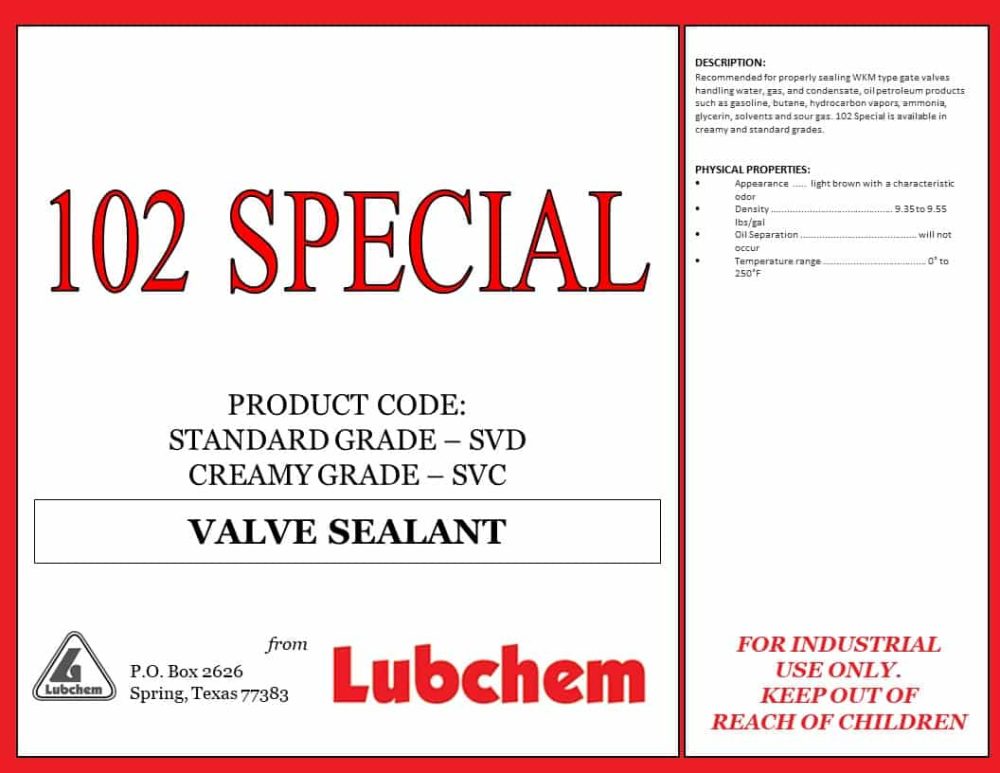

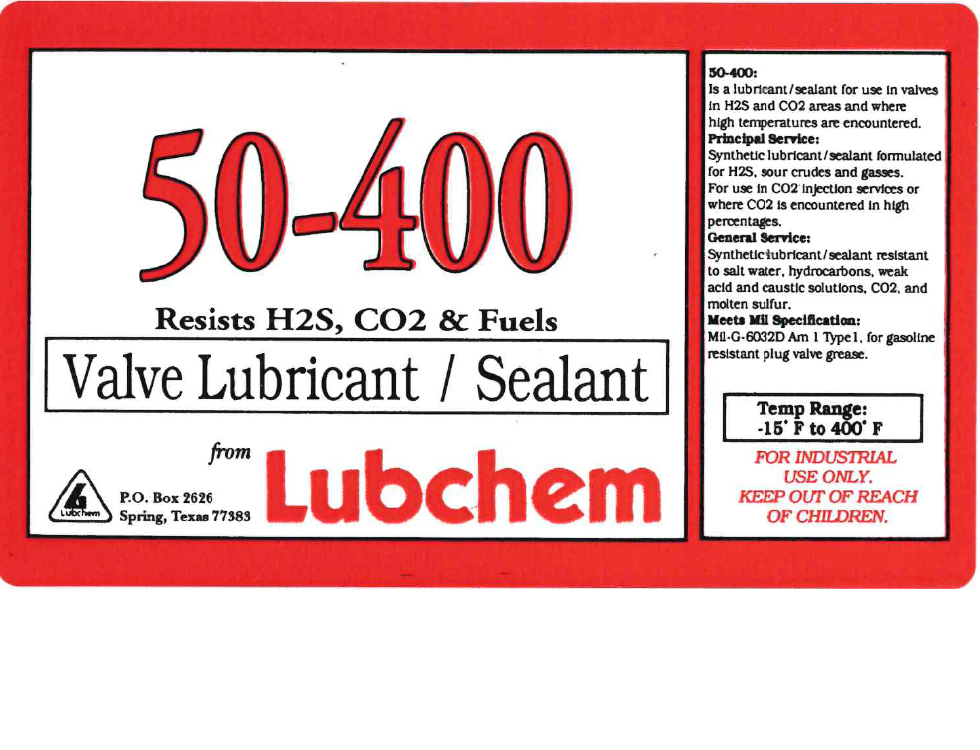

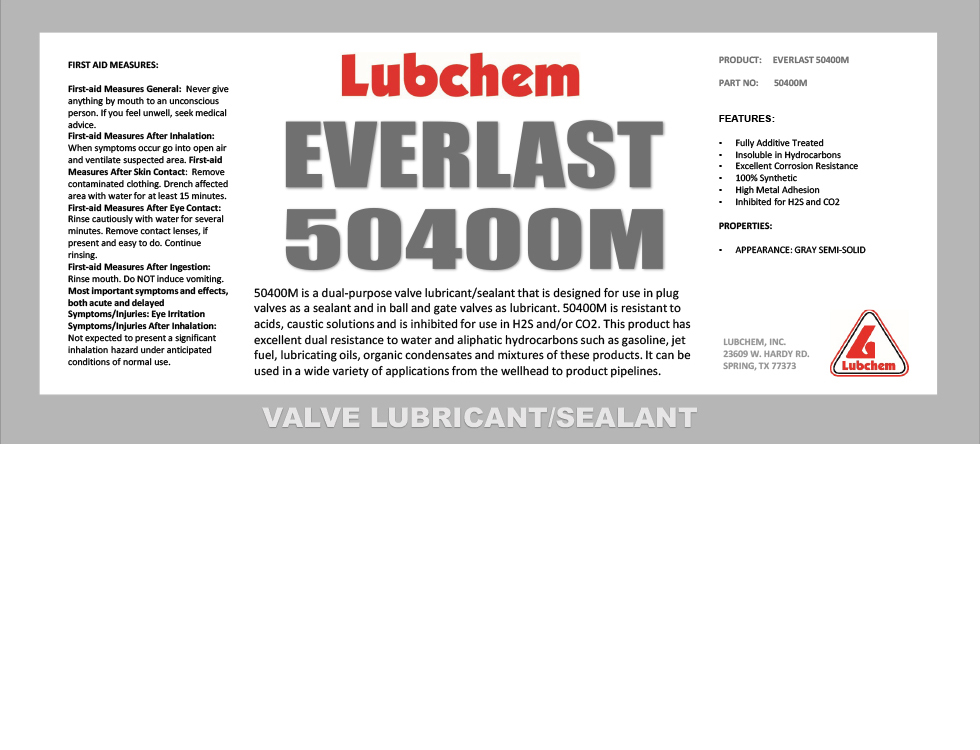

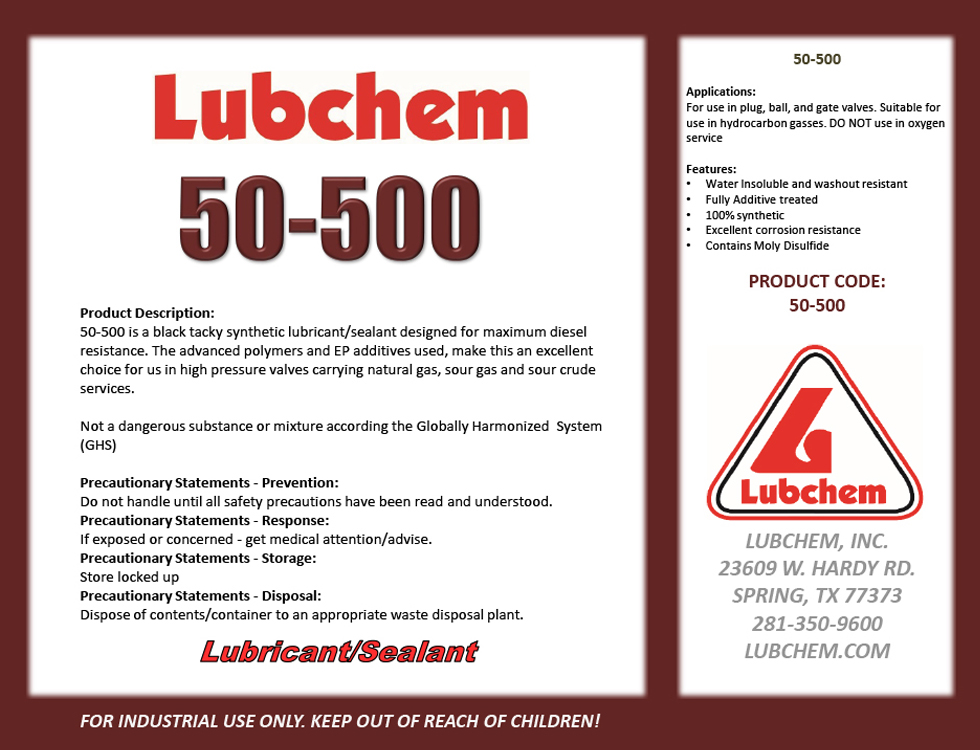

- Valve lubricants, for ball, plug and wellhead

- Valve cleaners & flushes.

- Emergency valve sealants

- Lubricants for equipment and maintenance

- Wireline Greases and Sprays

FAQ's

Lubricant specialties

Since 1952, Lubchem has been manufacturing a diverse line of chemical and lubricant specialties for oilfield, refining, petrochemical, mining, and general industrial applications. If Lubchem is new to you, we appreciate your interest. We trust you will find our site informative, and we hope you will visit often. If you are already one of our valued customers, we thank you for giving us the opportunity to serve you.

Valued Manufacturing

Since 1952, Lubchem has been manufacturing a diverse line of chemical and lubricant specialties for oilfield, refining, petrochemical, mining, and general industrial applications. If Lubchem is new to you, we appreciate your interest. We trust you will find our site informative, and we hope you will visit often. If you are already one of our valued customers, we thank you for giving us the opportunity to serve you.

Lubricant specialties

Since 1952, Lubchem has been manufacturing a diverse line of chemical and lubricant specialties for oilfield, refining, petrochemical, mining, and general industrial applications. If Lubchem is new to you, we appreciate your interest. We trust you will find our site informative, and we hope you will visit often. If you are already one of our valued customers, we thank you for giving us the opportunity to serve you.

Valued Manufacturing

Since 1952, Lubchem has been manufacturing a diverse line of chemical and lubricant specialties for oilfield, refining, petrochemical, mining, and general industrial applications. If Lubchem is new to you, we appreciate your interest. We trust you will find our site informative, and we hope you will visit often. If you are already one of our valued customers, we thank you for giving us the opportunity to serve you.

Lubchem V-Clean – Liquid Valve Cleaner

Since 1952, Lubchem has been manufacturing a diverse line of chemical and lubricant specialties for oilfield, refining, petrochemical, mining, and general industrial applications. If Lubchem is new to you, we appreciate your interest. We trust you will find our site informative, and we hope you will visit often. If you are already one of our valued customers, we thank you for giving us the opportunity to serve you.