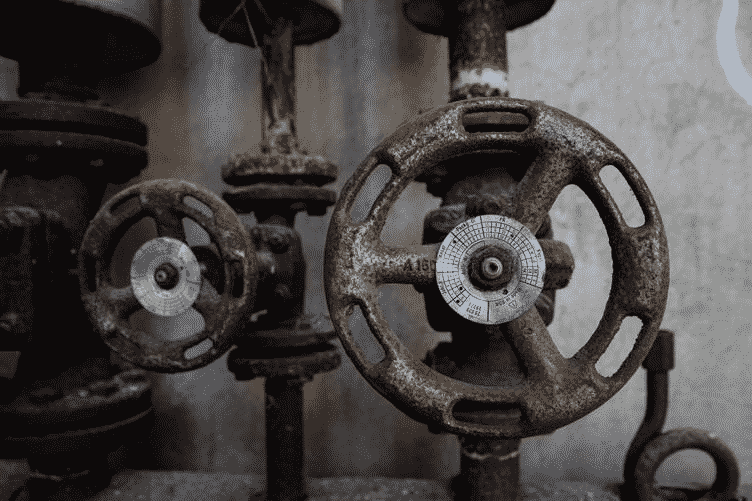

A quarter-turn on-off valve is known as a plug valve. The plug comes in several port types and can be cylindrical or tapered. Plug valves come in both lubricated and non-lubricated versions.

Non-Lubricated Plug Valve

A polymeric body liner or sleeve is put in the body cavity of non-lubricated plug valves. The polished, tapered plug serves as a wedge, pressing the sleeve against the body. The friction between the plug and the body is reduced by the non-metallic sleeve.

When little maintenance is required, non-lubricated plug valves are utilized instead of lubricated plug valves. Because they do not have a body cavity in open contact with the flow while switching, fouling liquids cannot be trapped or hardened, possibly clogging the valve, they can be utilized in particular services. There is no torque sitting on these valves.

Lubricated Plug Valve

Only inverted pressure balance lubricated plug valves will be utilized if the product permits the use of lubricant. The base oil and a viscosity improver, such as amorphous or fumed silica, are required in lubricants. They work effectively in procedures with mildly abrasive particles in the fluid. The tapered bores of the plug and body are matched to provide a reasonably large seat area. The plug bore is usually decreased, but the full port is accessible for slurry functions with significant solid content, where these valves are especially well suited. Full port valves are far more costly than reduced port valves, and they’re not usually utilized in hydrocarbon applications.

The lubricant or sealant creates a seal between both the plug and the body, protects the seating surfaces from corrosion, and functions as a lubricant, all of which helps to reduce the force necessary to open or shut the valve. The sealant is injected regularly, possibly every twenty procedures or after long periods of inactivity. It is possible to install an automated lubrication system. If the valve is not lubricated, it may become inoperable.

In most configurations, a jacking screw may be manually adjusted to elevate the plug off the seat. After such intervention, solids may become lodged between the plug and the seat, obstructing dependable shut-off. The sealant facility can occasionally be used to repair damaged seats back to service.

Lubricated plug valves are commonly utilized in filthy upstream applications where process fluid contamination is not a concern. The valves are, however, more costly, and heavier than ball valves. They’re also commonly employed as bypass valves for mainline ball valves, blow-down valves on valve stations, and kicker valves in gas pipeline systems. They can be made of unusual materials like duplex stainless steel and Inconel atop Inconel.

There is no torque sitting on these valves.

Double isolation plug valves may be used instead of two valves in series for double block and bleed non-piggable upstream applications when size and weight are a concern.

Eccentric Plug Valve

A plug valve with the plug sliced in half is known as an eccentric plug valve. The benefit of this design is that it provides a larger sitting force while reducing friction from the open to a closed state. Without a large increase in working torque, shut-off capabilities are increased. Torque is used to seat these valves.

Expanding Plug Valve

This expanding plug valve is a unique design wherein the plug is made up of many components that allow it to expand mechanically onto the cylindrical body by a wedging motion. Although pricey, these valves provide a real double block and bleed function in a single valve, which is great for preventing product contamination. These valves should not be utilized for maintenance reasons as a way of “double isolation,” as a single failure is still likely to impair both blocking functions.

Key design characteristics

As we know plug valves are the double valves with a cavity between the seats, or both above and below the stopper, and must satisfy the cavity relief requirements.

Non-metal-seated plug valves and non-lubricated plug valves with non-metallic sleeves used to handle combustible fluids might be equipped with an antistatic mechanism that ensures electrical continuity between the plug, stem, and valve body.